Abscess Packing Device

This project is a fantastic testament to the power of our streamlined product development process. By working with design-for-manufacturing in mind and a clear understanding of both the size of the opportunity and (eventually) the cost target for the device, our team was able to create a device that met aggressive functional, ergonomic and cost targets over the course of just a few weeks.

This pitch deck an example of the kind of deck an inventor might use to solicit funding for a new product or startup. Pixel and Timber has created product concepts and pitch decks such as these for a number of independent inventors. This is a powerful way to leverage the power of requirements-driven-design to create the financial foundation for a new company. (The contextual inquiry work cited in this deck was the work of the Medical Device Engine at UCMC.)

PROJECT BACKGROUND

This project was built on a patent filed by the University of Cincinnati Medical Center. (UCMC) The project had been explored by several classes of biomedical engineering students before it was transferred to the internal industrial designer at the Medical Device Engine (MDE), a medical device development startup housed within the Emergency Medicine Department from 2012 - 2014.

PRODUCT OPPORTUNITY

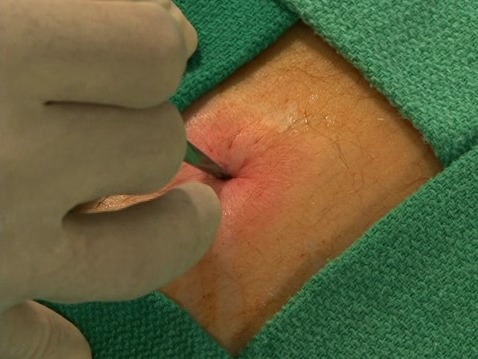

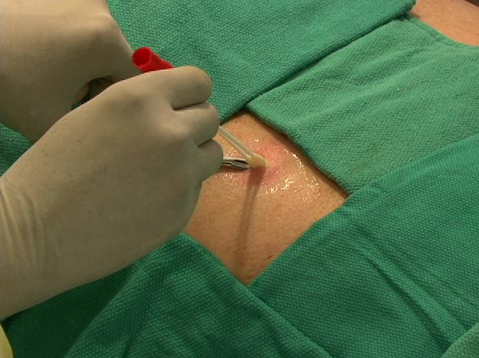

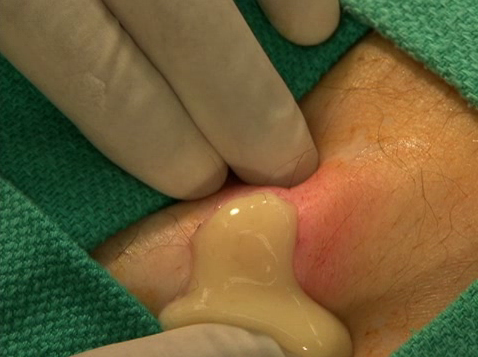

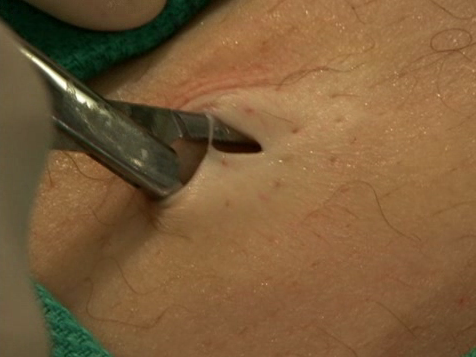

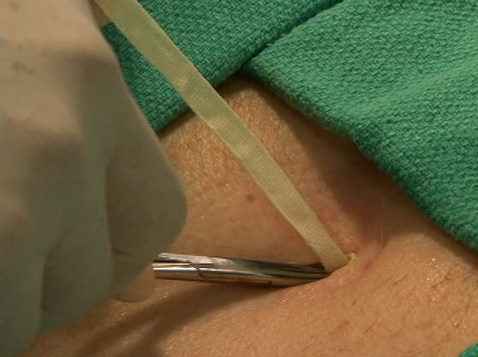

The opportunity for this project was to reduce the time and difficulty associated with packing a large abscess by developing a mechanism that could deliver a stream of packing tape (Curad, 3M, et al.) into the wound. As shown in the sequence below, after incising the abscess, the current method makes use of a hemostat to break up loculations and push tape into the opening. The process is difficult and time consuming and represents a drain on the hospital, because this non-life-threatening condition is often treated in the ED.

PROJECT DETAILS

The project unfolded in two stages. The first stage began before a cost target was determined and provided a solution that far exceeded the material needs of the procedure as well as the cost available for this portion of it. The second version was redesigned once a cost target was established. This vastly streamlined version of the device was inspired by a white-out tape dispenser and represented a massive reduction in cost and complexity. This project provides a fantastic testament to the need for starting with precise cost and volume targets as well as design requirements before beginning a project of event modest size.

VERSION 1 ($9.02)

In the first version of the device (shown in the video above), I designed a unit that would dispense tape slowly and at a controlled, variable rate. A sliding, color-coded tab was pulled backward to arm the device. Material was dispensed by pulling back on an ambidextrous lever atop the unit. The unit incorporated much more tape than would ever be used in an average procedure.

A short draft video of the earlier version of the device. This version included yards of sterile tape and variable dispensing.

VERSION 2 ($.82)

The chart above provided unit and tooling costs for the V2 (Rev. 3) version of the device.

The second version of the device represented a massive reduction in cost and complexity made possible by the establishment of some key requirements that had been missing from the previous effort and based on the new knowledge gained during that effort.

The final version was vastly simplified and included either a yard or a foot of tape.