Modular Multi-Hull Sailboat

Another small sailboat design from Pixel & Timber founder David Parrott. This early concept is designed for modularity, simplicity, and affordability. The design combines a handful of exciting ideas for the small boat industry, including a simple adaptor system to use conventional windsurfing sails, the idea of using reclaimed ocean HDPE for hulls, the simple thru-hull rudder attachment of our earlier designs, and a modular kit that can adapt and grow with its user.

This project is a continuation of earlier projects based on our interest in small sailing craft. Like our 16-30 Sail Canoe, this small craft is meant to make sailing more affordable and less elitist. It’s intended for the inland lakes that define the sailing scene much of the United States, but the versatility of its design makes it appropriate for coastal sailing as well. Its elements are designed for simplicity and ease-of-use. And the reclaimed ocean plastic hulls are meant to reduce the ecological footprint of its production and increase demand for this valuable (and increasingly available) resource. Like all of our independent designs, this project includes a heavy focus on design-for-manufacturing (DFM), and it is crafted around our principles of affordability, empowerment and sustainability.

“Many designers resist modularity for fear of limiting creativity. However, modules applied at the appropriate level will liberate designers from useless activity and allow them to focus creativity where it is most needed.”

Modular Design

The modularity of this design makes it adaptable to the unique weather and water conditions every of every user and their unique abilities. Its adaptability makes it the perfect fit for the inland lakes of the United States — a large, varied and underserved region that can’t realistically be served by a single dinghy design. This market is currently dominated by used boats designed and manufactured in the last century. Designed for areas with good wind, few of these are a good fit for most of the country’s interior. To make this design work for most of this underserved region, the boat can be purchased in three multihull formats: tacking outrigger, small trimaran, or catamaran. All three formats include a narrow, easily driven 18’ displacement hull that’s perfect for low wind conditions of an inland lake but will also work beautifully on a vacation to the coast, one of the Great Lakes, or to any other area with reliable wind.

Like purchasing a new automobile, the user should be able to buy his/her custom boat online by selecting several features, including the color and material(s) of various components.

Prior to purchase, users can configure all aspects of the boat online using a build-and-price feature similar to those used by automobile manufacturers. This modularity allows users to build a boat that’s right for them and the conditions in which they sail. It also allows them to upgrade their boat in the future through the purchase of additional components. As the design gains success, certain combinations of features will become endemic to those areas in which they work best. And by providing a handicap system based on the unique characteristics of each user’s boat, tying it to their profile, and utilizing a weather and position tracking app, users will be able to compete internationally, against other sailors with different boats, and without leaving their home waters.

The 18’ main hull includes an integrated cooler (with drain), thru-hull rudder and daggerboard slot. These features provide kiss-off or “almost kiss off”reinforcements to stiffen the HDPE hull. The catamaran includes a second main hull while both trimaran and outrigger versions are augmented with one or more outriggers (or amas). The deck area is slightly crowned for strength and to allow water to run off the hull. Its top surface includes molded texture areas for grip. All hulls are connected by a custom extrusion with a t-slot channel to accommodate the trampoline and additional bolt-on accessories. Inspection ports on the stern and in the cooler area allow fasteners to be installed within the hull.

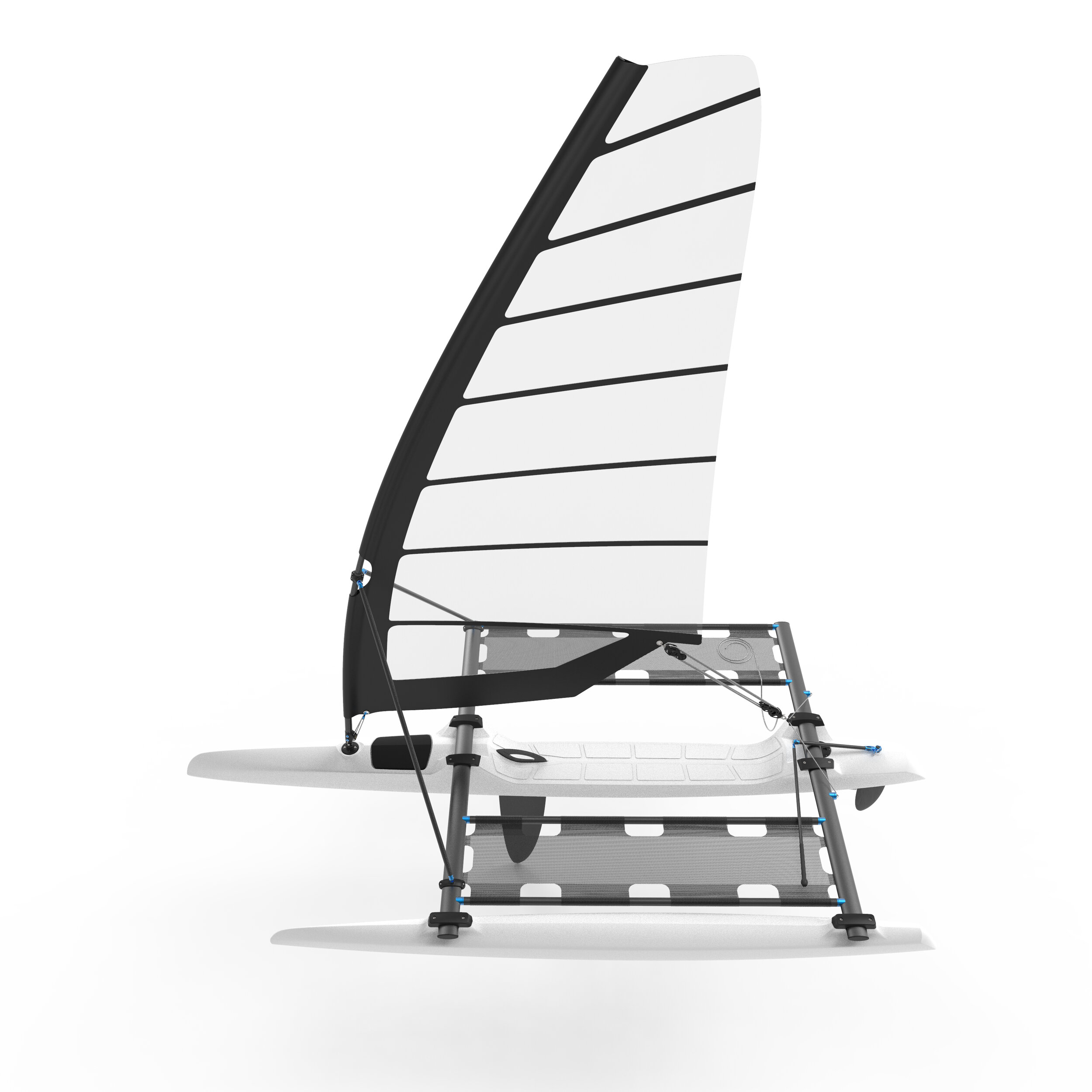

All 3 configurations take advantage of the high performance, modularity and affordability of the modern windsurfing rig, including its two-piece carbon mast, mast extension and universal mast base. The main hull includes a mast step designed to accommodate the universal mast base common to all windsurfers. This mast base is one of three attachment points that secure the mast vertically. The other two are a pair of carbon fiber struts clamped to the extruded crossbeams (akas). This tripod design supports and reinforces the mast and eliminates the need for the stub mast seen on many tacking outriggers. A custom clamp connects the struts to the mast, supporting it but still allowing rotation during tacks. (Future versions of this clamp may accommodate for a wishbone boom.) As a day sailor, this high performance rig doesn’t need reefing points, but the modularity of its design allows a user to swap his/her sails to accommodate different wind conditions.

Tacking Outrigger

The outrigger provides a lightweight, simple boat that can be easily trailered and hand-launched by a single person without the need for disassembly.

Its asymmetric design provides a uniquely exciting (and likely wet) experience for sailors who didn’t grow up with a Malibu Outrigger or similar small craft.

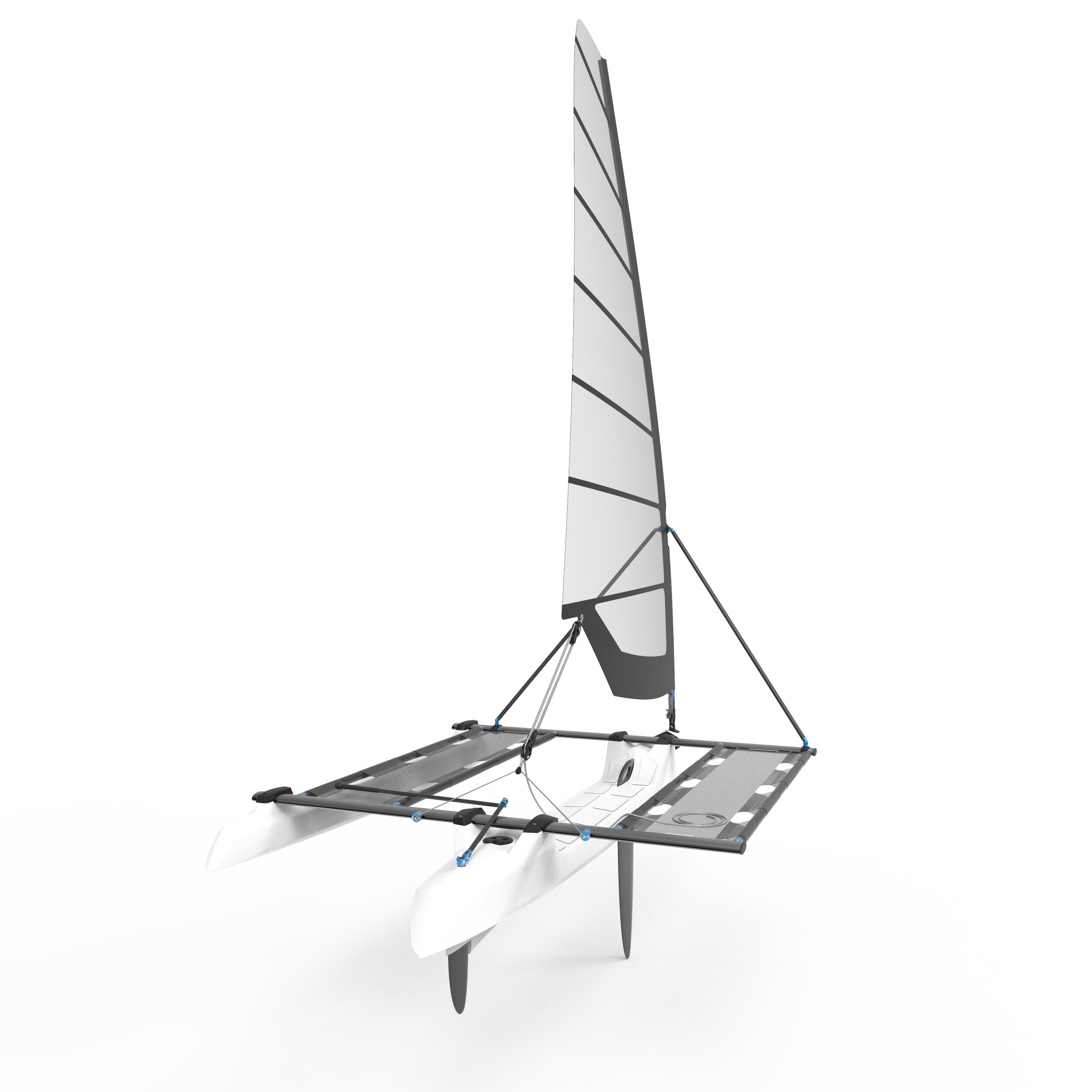

Small Trimaran

The small trimaran combines the easily-driven main hull of the outrigger with the stability of the catamaran.

Its increased beam (for hiking) and leeward ama provide greater righting moment. :Like the outrigger, narrow trampolines allow a user to paddle from the center hull.

Catamaran

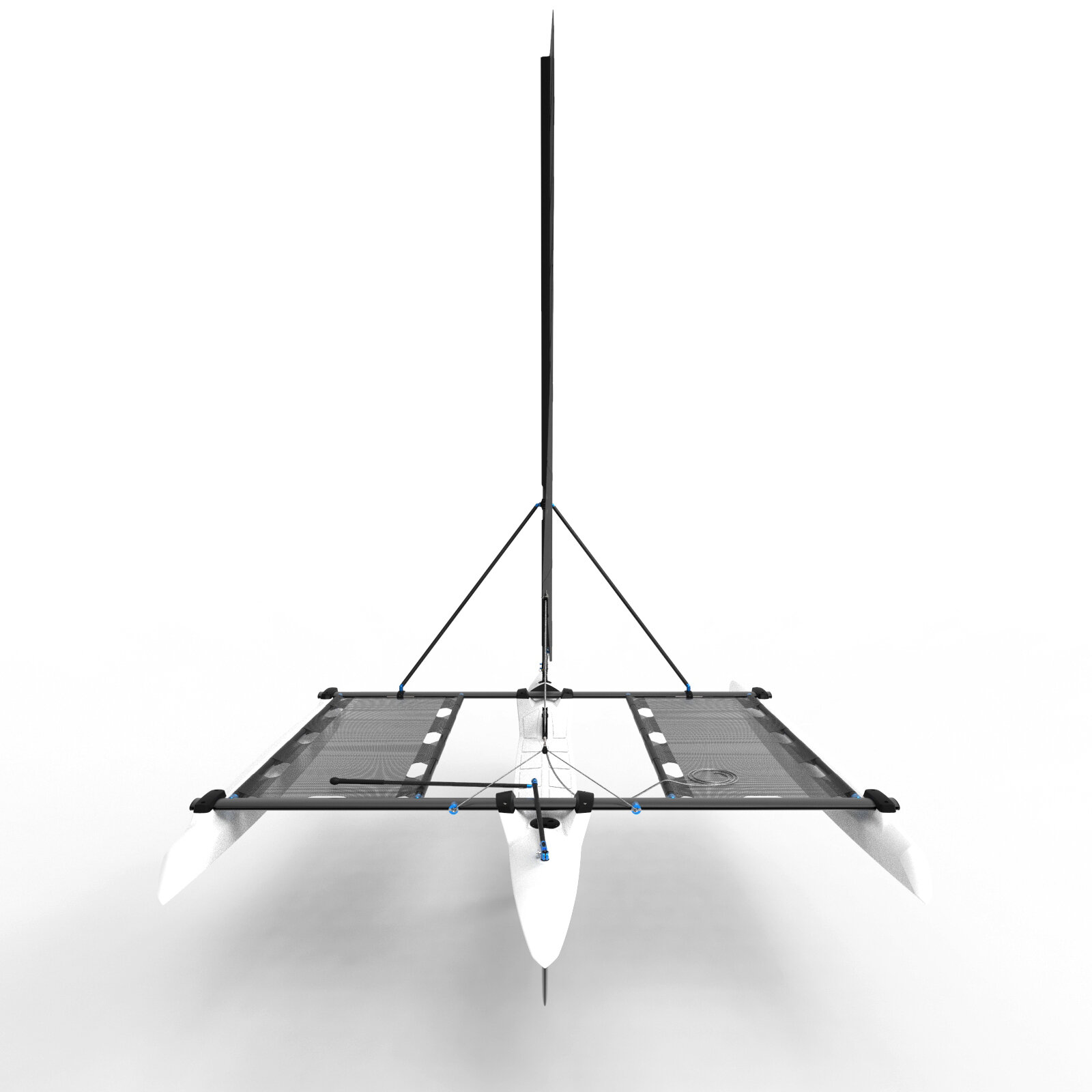

The catamaran format will be most familiar to the average sailor. It’s comprised of a pair of main hulls with a large trampoline stretched between. Additional hardware is added to connect the dual rudders.

In future embodiments, additional features may be added, including a strengthened mast and strut assembly and a furling jib.

Because the boat is to be user-assembled, it provides unique opportunities for both manufacturer and user. For the manufacturer, the cost of assembling and shipping a pre-assembled boat is reduced, as is the ecological impact of shipping. The user is afforded the opportunity to customize his/her boat by selecting unique combinations of colors and materials for its various components. Upon receiving an order, the manufacturer can print its manifest and pack the user’s package to match

Components for the catamaran version. Image shows white hulls, carbon fiber blades, and a combination of black and blue anodized components. (Hidden components include: sail, trampoline, running rigging and hardware.)

Common Features

Some of the key features that define these craft are highlighted in the space below. These include an integrated cooler in the foredeck of the main hull, a thru-hull rudder assembly, the mast base and clamp system that makes the use of windsurfing masts possible, and a textured area on the main hull (that probably isn’t worth mentioning).

Integrated Cooler/Storage

A small compartment just abaft the mast provides a waterproof space to store dry items. This compartment can also be used as a cooler. It includes a thru-hull drain in the bottom to allow melted ice to drain. The structure of this compartment is designed to increase the stiffness of the hull in this area. Inspection ports within this compartment allow access to the inside of the hull for the installation of thru-hull hardware.

Thru-Hull Rudder Attachment

Unlike many kayak rudders which are screwed to the outside of the hull, this rudder is attached using clamp-on fittings similar to the stem and steerer tube of a bicycle. The composite rudder is built like a bike fork with an aluminum steerer. The steerer slides through a molded tube that runs the full height of the hull, connecting and stiffening this area of the hull and deck. The stem (pictured in blue) clamps onto the steerer tube and attaches it to a composite tiller assembly.

Mast Base

To leverage the low cost and high performance of windsurfing rigs, the hull is equipped with a small mast step that accepts a universal windsurfer mast base. This allows nearly any combination of mast, extension and sail to be used with this hull. By pulling the quick release in the mast base, the entire rig can be folded flat along the trampoline or (with a different sail) arranged as a tent. The thru-hull hardware for the mast base can be easily installed through the forward inspection port within the cooler.

Mast Clamp

One embodiment for a custom mast clamp is shown here. This clamp connects the mast to the crossbeam (or aka) by way of composite struts. With the mast base and two struts, the result is a stable tripod shape with the mast supported at just below its halfway point (the same level at which a boom would typically be attached). The three-part design of the clamp allows the mast to pivot while still providing vertical and horizontal support. This embodiment is shown with quick-release pins. These allow the entire rig to be disassembled without tools.)

Textured Deck

Like other rotomolded hulls, this one takes advantage of the multiple textures that can be imparted to its tooling to provide a textured deck. This increases the grip in this area of the deck through which a sailor will cross during tacks. In low wind, the user is likely to stand in this area and use the paddle of a standup paddleboard to paddle in the space between hull and trampoline.

Sustainability

The ecological footprint of every product is the sum of its impact during production, use and reclamation (or destruction). While the lifetime impact of a sailboat is small compared to other more fossil fuel thirsty watercraft (e.g. motor boats), their production and destruction both represent large areas for improvement in terms of sustainability.

Their composite hulls can’t be broken down into raw materials. They can’t be economically recycled. So where do fiberglass boats go to die? The landfill. That’s where.

The hulls of composite boats (e.g. fiberglass, carbon fiber, et al.) are what sustainability experts refer to as “monstrous hybrids.” These are products made from multiple materials that cannot be separated or reclaimed at the end of their useful life. Fiberglass boats are notorious monstrous hybrids. As anyone who has tried can tell you, there aren’t many options for discarding an old fiberglass hull. And there are fewer still for recycling. Only recently have programs like the Rhode Island Fiberglass Vessel Recycling (RIFVR) found ways to use shredded fiberglass hulls (and that is as fuel for cement kilns… not an entirely satisfying solution). Overseas, other programs have been created to chemically “separate a boat's polyester and fiberglass, allowing both parts to be reused.” Despite recent developments in fiberglass recycling, the industry is in its infancy. Currently, the landfill remains the most likely end-of-life solution for a composite boat. And many of the fiberglass boats produced during the 1970s and 80s are now reaching the end of their useful lives. Today, we are just seeing the beginning of a looming environmental crisis on the horizon as the first of this glut starts to make its way to landfills.

Using sailboats or human-powered boats to (silently) enjoy the outdoors can go a long way to reduce the ecological impact of the boating industry. But sourcing alternative materials and employing a design-for-disassembly strategy can reduce the impact of these watercraft still further.

Discarded fishing nets represent a major hazard to ocean life and a large component of the Great Pacific Garbage Patch. Most fishing nets are constructed from HDPE — the same material from which most rotomolded kayaks are produced.

According to a 2018 study by Ocean Cleanup, “46 percent of the plastic in the Great Pacific Garbage Patch is from discarded fishing nets.” These nets represent a large component of the GPGP, and in any place they’re found, they have a devastating effect on marine life. But these nets also represent an opportunity. Companies like Bureo, Oceanworks and others have started programs to reclaim or intercept these nets and make their material available for new products, and their work has found its way into the mainstream. Humanscale’s Smart Ocean chair incorporates “almost 2 pounds of recycled NetPlus material” from Bureo. But like many other plastic products, the total volume of reclaimed resin it can contain is so small, its production is unlikely to cause sufficient demand to bring down the cost of these reclaimed materials.

Meanwhile, the weight of an average rotomolded kayak ranges from 30 - 60 lbs., nearly all of which is found in the hull — a rotomolded structure made from one material that’s easily separated from other components. And like many fishing nets, most kayaks are made from high density polyethylene (HDPE). This means that by processing reclaimed ocean HDPE as rotomolding powder, every kayak produced from this material could reclaim up to 60lbs. of ocean plastic.