GE360 Foam Wash

With a GE90-powered Boeing 777, foam wash has the potential to save an estimated 35,500 gallons of fuel and 380 tons of CO2 emissions per year compared to GE90 engines cleaned with water wash.

This project demonstrates the power of design to deliver groundbreaking technology in a user-driven package. During this project, Pixel and Timber collaborated seamlessly with GE Aviation and Rhinestahl to create a novel, user-driven platform for GE’s innovative foam wash technology. The video below outlines the benefits of the GE360 Foam Wash system.

“I had the pleasure of working with David on a project for GE’s aviation services division. We at GE had built a first generation design for a specialized maintenance procedure. We hoped to improve the functionality, ergonomics and aesthetic of the equipment, so we engaged David and his team to work on the next generation.

Over a short period of time, David and his team interviewed dozens of stakeholders, observed the equipment in several environments and led design/brainstorming sessions. The result was beyond everyone’s expectations. When we took the new unit to airline hangars, the mechanics invariably were drawn to this machine and wanted to work with it. It looked like no other equipment in the hangar, except the airplanes themselves. ”

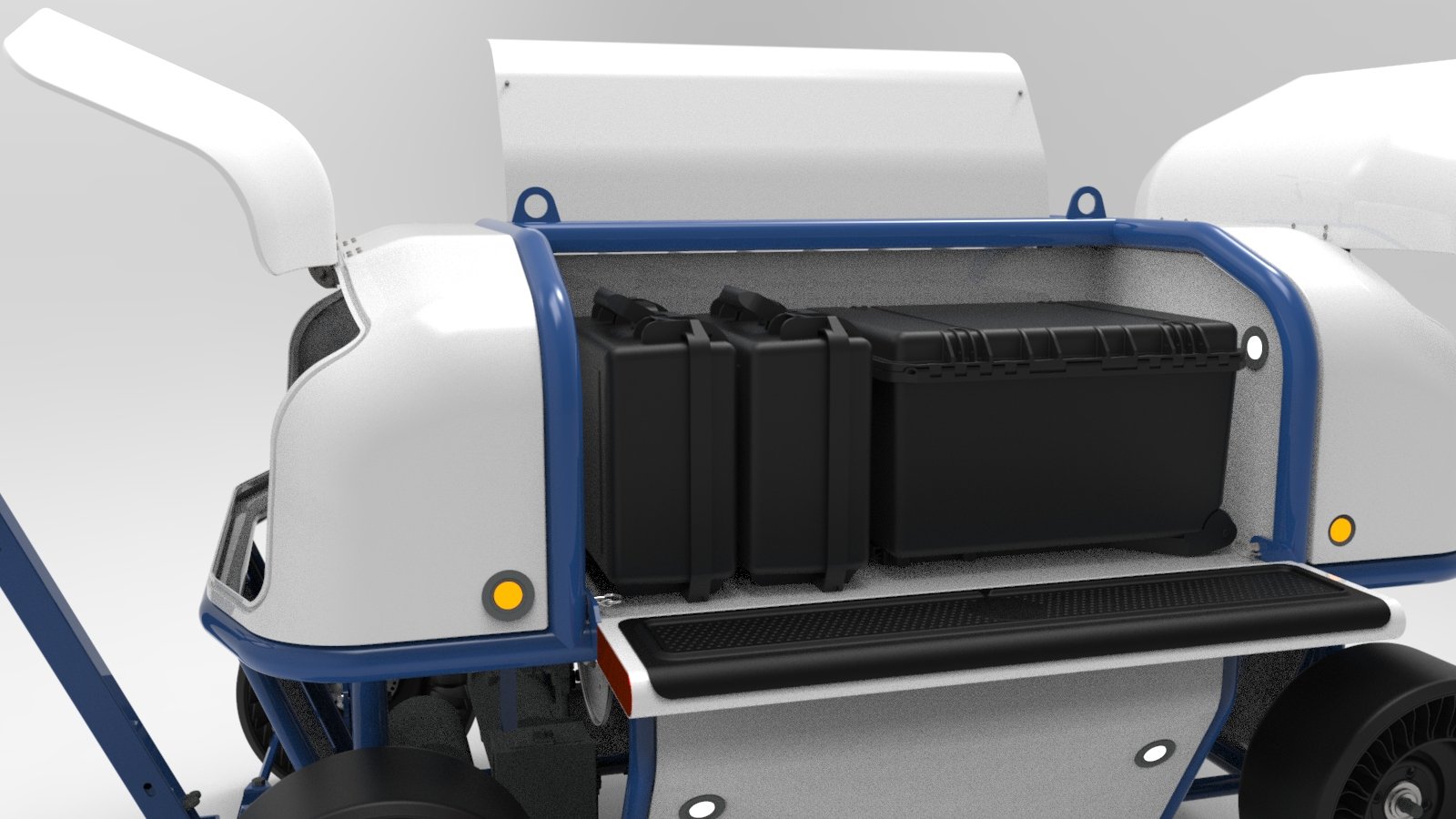

Like other professional equipment, the success of GE360 hinged on the marriage of GE’s innovative foam wash technology and an outstanding user experience. To deliver the latter, Pixel and Timber observed GE’s on-wing support teams performing washes in multiple locations before distilling our insights into the device pictured below. This project incorporated many of Pixel & Timber’s specialties, including contextual inquiry, live ideation, collaborative concept design, CAD development, and fabrication.

Concept Design

Production Device(s)